Hello Everyone,

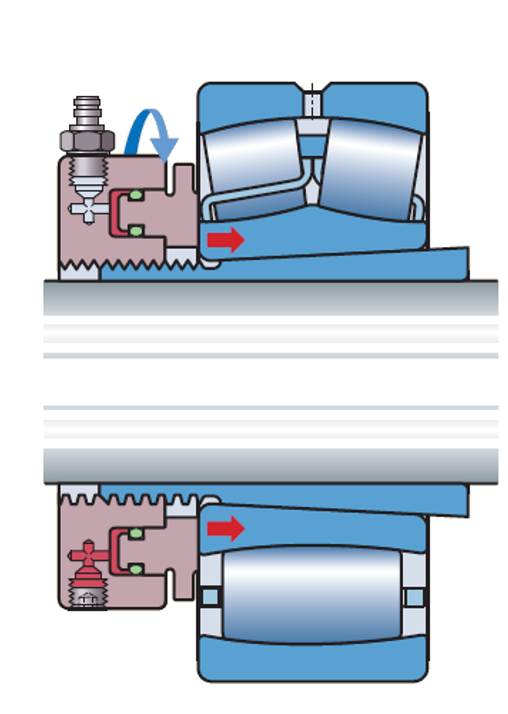

Thank you for the great feedback! Some additional information based on the feedback, this bearing assembly is a specialty design. It is the NDE bearing (fixed bearing) on a mine ventilation fresh air supply fan ( as stated, custom design for the NDE bearing is typically floating in my experience). Since it supplies fresh air for underground, it is quite large, ~10.5' fan diameter. The NDE bearing is two bearings, a thrust and double spherical roller bearings with a spacer in between, assembled in a cartridge, placed in a pillow block. There is a locknut & washer to fix in place, which, from my experience is typically used on taper shafts. However, this shaft is not tapered, it is straight. The bearings are fitted on the shaft via a transitional fit, based upon discussion among the Team, there is belief it should be an interference fit and the locknut/washer is not the proper application. Also, questions on the locknut torque, 1000 ft lbs, dry. The torque appears quite high, hence, what is the clamping force to hold the assembly on the shaft? Is this locking assembly able to provide sufficient clamping force? Supposedly this design was utilized because of the significant axial force created by the fan.

Due to the cartridge, it is very difficult to torque the locknut.

There is a brake but not necessarily applied when the fans are shutdown. I think it is applied when the fan is locked out for maintenance. Interesting enough, currently troubleshooting issues on one of the other fans (as per below, we have 8 of these model fans on site) where it tripped on high vibration. At first, we were pinning it on an electrical fault/interference or faulty sensor(s), but further investigation, we believe we can rule that out including the fact the fan was shutdown (motor off so no current/electrical feed) and the fan was "freewheeling". With the movement caused by draft air, we still experienced concerning vibration amplitude level, hence, believe it is mechanical. Difficult to troubleshoot with the online system since it is only an overall vibration level/amplitude, no spectrum. Since we were having issues with the fan that is the subject of this post, we installed sensors and cables to allow collection with the AMS 2140 (cannot access fan bearings, etc. during operation). We are planning on installing hardware on all the fans to allow data collection with the 2140.

.

In regard to the failure, further details below;

On January 27th;

- Dominant vibration was 2X running speed with low 3X. 2X peak is approximately 3.5 mm/sec in amplitude (y-axis).

- Overall amplitude was within acceptable range per OEM and industry standard (ANSI & ISO).

- Same 2X running speed vibration was present in baseline readings (when commissioned) but lower amplitude. Change in amplitude from baseline was a trigger to monitor closely.

On March 29th;

- Multiple peaks that are separated by running speed of fan. Each peak ~4 mm/sec in amplitude (y-axis).

- Pattern typical of looseness (loose fit of brg to shaft).

- Based on the changes noted, recommended shutting down the fan & replacing bearing.

The fan was commissioned in May 2021, slightly below 3 years of operation at time of failure (premature failure).

The washer had two failed tabs & the locknut was loose. Also noted by our maintenance team that the tabs on the washer were not fully engaged into the locknut. In addition, the fan shaft was undersized but believe to be caused by wear on the shaft from the bearing failure. However, we did find on a separate fan (8 total of this specific model on site, some in operation, some soon to be handover for operation) that the shaft was indeed below spec diameter, hence a theory is the shaft was undersized on this specific fan as well? Review of the inspection reports (available for most fans, not all yet commissioned as stated), all shaft dimensions were acceptable. Also, no bearing clearance checks pre & post-install available.

The following damage characteristics were noted;

- Sub-surface fatigue/adhesive wear between bearing inner races & shaft & between interfacing surfaces in axial direction.

- Spalling/flaking, gouging, scoring, smearing & skidding present.

- Signifies relative rotation between the components or creep.

- Fretting corrosion on spacer surface contacting shaft & outer ring of double roller bearing.

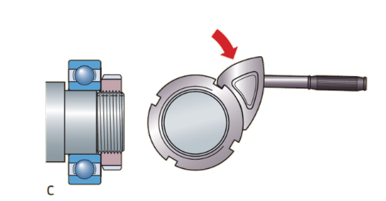

- Two lock washer tabs sheared off – one outer diameter tab and the inner diameter tab that mates with the shaft keyway. There are several outer diameter tabs that engage with the locknut.

- Fracture surface features consistent with fatigue from in service cyclic loading (beach marks or progression lines or striations).

- Discoloring from heat generated but believed to be auxiliary damage (present on DE bearing & pillow block as well). Grease in areas was dark/black from heat.

------------------------------

Chris White, P. Eng., SMRP

Senior Reliability Engineer

Vale

Newfoundland and Labrador

------------------------------

Original Message:

Sent: 06-06-2024 03:22 PM

From: Johannes Harmzen

Subject: Mine Ventilation Fan NDE Bearing Failure

Hi Chris,

There may be a variety of causes for the locknut backing of.

- Bearing drive up

- If the bearing is not driven up sufficiently, there may be movement (rocking of the bearing on the adapter sleeve) that can cause the locking tab on the lock washer to wear or even shear off, causing the locknut to move.

- Correct drive up is ideally achieved using an hydraulic nut - this is the most accurate and repeatable way to ensure the bearing is pushed up sufficiently onto the adapter sleeve taper.

- Undersized shaft might contribute to insufficient drive up.

- Never use a cold chisel to drive the lock nut. Use a C-spanner or impact spanner.

- Temporary change in axial load direction

- During start up or in some circumstances in the process, the axial load may push in the opposite direction of what it was designed for. This can cause a loosely fitted bearing to move down the taper of the adapter sleeve, or add additional force on the locking washer.

- Is there a stop (brake) on the fan when it is not working? An induced draft can push/pull the impeller in the opposite rotation of what it is designed for, causing the movement of the bearing down the taper of the adapter sleeve, or movement of the whole bearing sleeve arrangement on the shaft (under mounted bearing arrangement)

- Contact of the lock washer with a stationary part

- Is there anything in the arrangement that is close enough to touch the shaft / lock nut during rotation? This contact may happen after wear in the bearing causing additional movement (in this case the root cause would be wear - from lack of lubrication or ingress of water / dirt)

- If the bearing is not driven sufficiently, the bearing and adapter sleeve can move on the shaft and cause the lock nut to touch the housing / end cover.

- Insufficient movement of the arrangement to allow for thermal expansion

- Normally the NDE side id the expansion or 'loose' side of a bearing arrangement. Check if the bearing OD can move in the housing (depending on the arrangement)

- Rust in the OD, rough surface, or housing bore out of tolerance are normally the main causes. Misalignment may also be a cause of preventing movement of the bearing in the housing.

I would suggest looking at all the components to look for the root cause. Are there radial scores on the inside outside of the adapter sleeve - indicating rotation of the bearing on the sleeve or the sleeve rotating on the shaft. What does the grease / oil look like in the failed assembly? Is there evidence on the lock nut side face of contact.

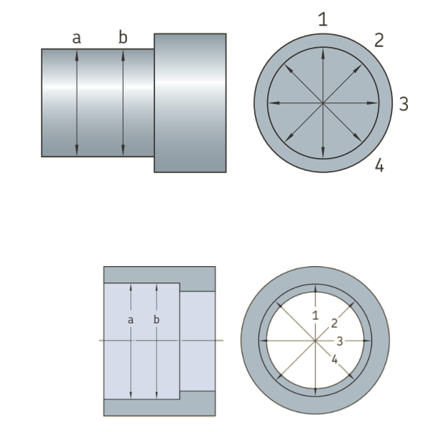

Also look at installation practices and if available, records from installation. Shaft measurements, drive up values or bearing bench clearance before mounting and bearing internal clearance after mounting.

Definitely record these values when you mount new bearings.

Hope it helps.

------------------------------

Jaco Harmzen

REP Engineering Manager

SKF USA Inc.

Conshohocken PA

Original Message:

Sent: 06-05-2024 02:18 PM

From: Terry Dean

Subject: Mine Ventilation Fan NDE Bearing Failure

Chris,

On this type of locking device, there should be a tab to prevent the locking washer from moving. I've seen applications were the installing mechanic will not get this tab located properly. This damages the tab that should be located in a slot on the shaft and the nut will loosen due to the vibration of normal operation.

------------------------------

Terry Dean

Reliability Engineer

Pharmavite, LLC

West Hills CA

Original Message:

Sent: 06-02-2024 07:01 AM

From: Chris White

Subject: Mine Ventilation Fan NDE Bearing Failure

Hello Everyone,

Our Operation experienced a failure on the NDE bearing assembly of a Underground Mine Ventilation Fan (provided fresh from the surface to Underground). The bearing or bearings is a specialty design due to the thrust forces from a fan of this size & magnitude. The Fan is designed and supplied by one of the major manufacturing companies (not too many out there to my understanding) and is a fairly recent application, in discussions with the OEM, they estimate the bearing assembly was first introduced to the market in 2012/13 and ~30 to 40 fans in operations with the same/similar bearing assembly (~10 within our Company). We were informed that there was one other failure in a mine in Quebec but unaware of the exact failure mode and causes, OEM stated additional failures they are aware of but typically related to the use of incorrect grease.

This is the second failure within our company (a second failure from one of the operations in Ontario, Canada). Basically, the locking mechanism (locknut & washer) came loose. The fan was commissioned in 2021. Just reaching out, even with the low chances, of finding anyone with similar experience?

------------------------------

Chris White, P. Eng., SMRP

Senior Reliability Engineer

Vale

Newfoundland and Labrador

------------------------------