Thanks for the update Chris! Good luck with the trial.

Original Message:

Sent: 06-02-2024 06:33 AM

From: Chris White

Subject: Pebble (Cone) Crusher (Sandvik CH430) Failures

Hey Connor,

Apologies on the late response, a lot of discussion over the past few months with Maintenance & Operations on how to proceed with preventing/mitigating failures on the Pebble Crusher. We also had the OEM on site for training and a rebuild this past March.

You are correct in regards to the grease, the spec called for a NLGI 0 or 00, we were using a NLGI 1. The viscosity of the grease in use did not comply with OEM specifications as well. We have procured grease that complies with OEM specifications and it is now on our site (procuring materials and shipping to a remote site can take some time). Long story short, we are going to trial the proper grease before making any additional changes/modifications. That appears to be the key issue and cause.

------------------------------

Chris White, P. Eng., SMRP

Senior Reliability Engineer

Vale

Newfoundland and Labrador

Original Message:

Sent: 12-07-2023 02:59 PM

From: Connor Schriver

Subject: Pebble (Cone) Crusher (Sandvik CH430) Failures

Really appreciate the updates Chris. Looks like you've got a good handle on everything. I may have dreamt it up, but I believe I saw something in the online manual about using a NLGI 0 or 00 grease for the spider bearing - unfortunately can no longer access the manual to verify.

Looking forward to hearing the results of your findings!

Connor

------------------------------

Connor Schriver EIT, CMRP

Asset Management Consultant

Ausenco

Fernie BC

Original Message:

Sent: 12-06-2023 10:56 AM

From: Chris White

Subject: Pebble (Cone) Crusher (Sandvik CH430) Failures

Hi Connor,

Thank you for the continuous feedback, much appreciated!

I believe most inquires were answered in the response to Benjamin's reply, but will address the additional inquires below;

The grease used is Petro-Canada Precision Synthetic (see attached data sheet/SDS), it is a NLGI grade 1, lithium-based grease. The viscosity is lower than specified by the OEM but given the grease does not appear to "flow" through the bearing ports, a less viscous grease probably does not hurt (but still not reaching the bearing). I think the main issues is a lack of lube and the grease is not reaching the contact surfaces via the bearing ports but with that said, open to changing the grease type. We have not thoroughly reviewed the OEM recommendations with the technical data on the product in use but will do so. Overall, a modification to the grease system is required including an addition of an actual grease pump and tubing connecting grease ports for one solid line that is pressurized straight to the bearing.

Agreed that the grease is not supposed to be on the outer surface of the bearing but for some reason it is and, with the reason stated above, it is not greasing the actual contact surfaces that require lubrication (seems the grease can "slump" between the bearing and top shell bore, which, in my opinion, points to the issues with the "design"/method/function of the existing grease system).

There are no signs of grease on the actual mantle shaft, hence, another element/piece of evidence that the bearing is not receiving grease but agree this should be a formal inspection. In the discussion I had with my colleague as mentioned in the response to Benjamin's latest post, he recommended during rebuilds, we should apply grease via the grease pump prior to start-up, confirming there is some leakage around the mantle shaft.

I agree that additional checks for grease in the spider cap/bearing housing from the observation port is required.

There is a thermography route, but it is focused on the pinion shaft housing. A scan of the spider bearing is a good idea. There is a vibration route as well but issues with collect the data since the threaded mounts for the accelerometer are often buried in ore, etc., hence, we are reviewing permanently mounted online sensors.

Any additional questions and/or concerns do not hesitate to contact us.

Thank you

------------------------------

Chris White, P. Eng., SMRP

Senior Reliability Engineer

Vale

Newfoundland and Labrador

Original Message:

Sent: 12-04-2023 11:21 AM

From: Connor Schriver

Subject: Pebble (Cone) Crusher (Sandvik CH430) Failures

That information deck is great, thanks!

Per Ben's post, some amount of grease leakage is to be expected, and from the cap & top shell photo attached there didn't appear to be much, although from the angle it's hard to tell. Re-greasing every 2-3 days for this type of application may be too infrequent, especially one that is designed to be greased at a high frequency (every few hours) by a set system. Grease on the external of the spider bearing I don't believe indicates much, as it really shouldn't be getting there anyways (torque/tolerance issue?).

Definitely would still be interested in the grease type. With the typical NLGI 2 grease used across the plant, it may be an issue of supplying grease with too high of a consistency to properly work its way through the ports/bearing. Mixing grease could also lead to these type of issues.

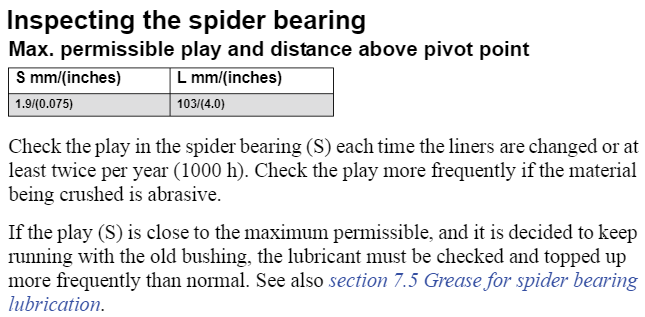

As Ben mentioned, the tolerancing could be a problem. Online OEM manual asks for the following check & tolerance:

Overall it's a decision between whether its a retaining or supply issue. Note that you can technically get through a retaining issue by overcorrecting the supply issue, at an expense. I've included some tests that may help identify the retaining/supply issue. Not sure what access to the equipment is like so may not be very applicable, without factoring in typical operations avoidance of any downtime (even for troubleshooting major issues).

- Observation port inspection for grease level at frequent basis (weekly, if failures are monthly)

- Top of mantle inspection for grease leakage (per Ben's photos) (same frequency as observation port, at same time)

- Thermography readings (likely immediately after equipment down, same frequency as observation port. Interesting to take them with different greasing/frequency intervals)

- Increasing greasing quantity/frequency short term and seeing the effect (MTBF increase? Decreased damage when failed?) Would want to mimic daily OEM grease system quantities for this, and would help justify the upgrade.

Seal upgrades are never a bad idea at the end of the day, and may save money just based on a better contact leading to more grease retainment. It's also good practice to change the seals whenever the opportunity arises.

------------------------------

Connor Schriver EIT, CMRP

Asset Management Consultant

Ausenco

Fernie BC

Original Message:

Sent: 12-02-2023 02:43 PM

From: Chris White

Subject: Pebble (Cone) Crusher (Sandvik CH430) Failures

Hey Connor & Benjamin,

Great feedback & inquiries! I have attached a pdf with a few pictures, schematics and additional information/responses to the inquiries. Let me know what you think and/or if there are any additional questions!

Thank you

------------------------------

Chris White, P. Eng., CMRP

Senior Reliability Engineer

Vale

Newfoundland & Labrador

Original Message:

Sent: 12-01-2023 03:10 PM

From: Benjamin Prior

Subject: Pebble (Cone) Crusher (Sandvik CH430) Failures

Hi Chris,

Agree with Conor's (and your) assessment on the mantle sleeve. I'm also with Conor on the seal. Any chance you can share some images of the seal design? I'm also not familiar with this make and model of cone crusher. I've mainly worked with Metso and FLS units which have a different setup.

The spider seal does sound somewhat similar to a Metso gyratory crusher spider seal however. These typically have a dual seal toward the bottom of the bearing and oil (460 EP Gear Oil) is injected above the bushing to gravity feed down to the seals. The cavity at the top of the mainshaft should maintain an oil level of about 1" above the top of the bushing in this design:

Could just be an under-lubrication issue? Hand greasing a similar seal design might not be sufficient?

------------------------------

Benjamin Prior CMRP, BEng, MBA

Principal

Priority Consulting Inc

Berkeley CA

Original Message:

Sent: 12-01-2023 11:28 AM

From: Connor Schriver

Subject: Pebble (Cone) Crusher (Sandvik CH430) Failures

Hey Chris,

I haven't dealt with this exact model, but here are the questions that I would be looking into (which you may already have ruled out). Of course armchair analysis only goes so far, so take my input with a grain of salt.

Spider bearing failure:

I would be hesitant to jump to design error right away.

Questions to ask:

- Is the seal OEM & designed for grease? Some models are oil lubricated. Is the seal changed frequently and kept in good shape?

- Is the correct grease in use? I assume in this application a thinner grease would be ideal (NLGI 0, 00 – ambient temperature may factor in)

- How often is it greased? Is grease allowed to harden up in the lines/in the ports? Is the delivery system purged on a frequent basis? Is the housing kept topped up with grease?

- Is the seal installed the correct orientation?

- Are the bearing ports being lined up properly during installation with the greasing system inlet?

- Are components pre-lubricated during installation with voids packed before operation?

Mantle Sleeve Failure:

Your assessment seems spot on. The excessive movement caused by the lack of fit will lead to a few issues in an asset. I would add that the lack of lubrication in the spider could also contribute as the counter friction could help spin the mantle sleeve off. The press fit upgrade may just be to make installation easier for sites, as not everyone will have access to oil baths - improper fit due to shaft wear will still be applicable and remain part of a good QA/QC program.

Best of luck with your troubleshooting!

Connor

------------------------------

Connor Schriver EIT, CMRP

Asset Management Consultant

Ausenco

Fernie BC

Original Message:

Sent: 11-30-2023 04:09 PM

From: Chris White

Subject: Pebble (Cone) Crusher (Sandvik CH430) Failures

Hello Everyone,

This is my first time posting here but wish to pick the brains of my peers related to a defect elimination project we are currently progressing. My name is Chris & I am a Senior Reliability Engineer for a Nickel & Copper mine, focused on fixed plant/concentrator operations. A Pebble Crusher utilized for oversize discharge from a SAG Mill Grinding circuit was identified as the number one bad actor for the plant. The Pebble Crusher is a Sandvik CH430. Various failure modes have occurred over the life of the asset but a few of the main and recent failures are;

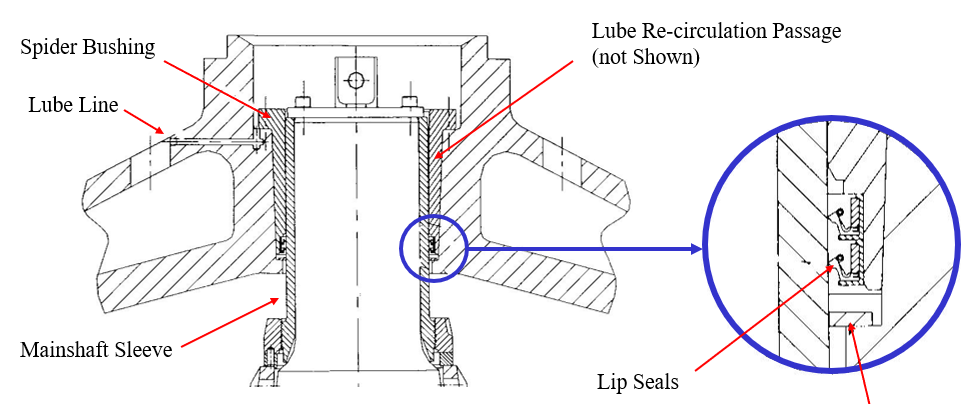

- Spider bearing and seal failures – there are no signs of lubrication on the spider bearing, it is dry as a bone, rusty and major scoring/gouges in the bearing (at times the bearing is also cracked). This type of damage is apparent after (only) a month of operation. The apparent causes are inadequate lubrication caused by a failure of the seal (inappropriate seal for the application), causing the bearing to lose grease or grease is not reaching the bearing in the first place (I, personally, believe this is the cause since the are no signs of grease even touching the bearing/mantle shaft/mantle shaft sleeve). The bearing is greased manually through a grease line. The line runs through the top shell assembly into/onto the housing/top of the bearing. Ports on the top of the bearing are designed to transfer the grease to the bearing seal and surface of the inner race in contact with the mantle shaft sleeve (it is a bushing/journal type bearing). There is grease on the ports from the grease line to the housing/top of the bearing but do not believe the grease is transitioning to the inner race/seal.

- The latest failure (this month), the actual mantle shaft sleeve between the Spider bearing & mantle shaft came loose, knocking of the Spider cap and falling into the crusher itself. The mantle shaft was in very poor condition so a rebuild completed about a month prior lacked QA/QC due to utilizing a shaft that did not meet specifications (also, lack of a rebuild procedure). It is believed the sleeve came loose due to excessive clearance between the sleeve and shaft. Also, excessive clearance between the spider bearing and sleeve contributed to the failure since the findings above were present in this failure (similar spider bearing damage absent the cracks). We did note that Sandvik, over the past couple of years, started supplying a modified shaft. The new style shaft is tapered with a sleeve that is applied utilizing a hydraulic pump, press fitting the sleeve onto the shaft. The old style shaft wasn't tapered and recommended an oil bath for the sleeve to bring within a specified temperature for an interference fit onto the shaft. We were wondering if the shaft was redesigned because of similar issues/common failures to the failure modes experienced by our operation?

We have been in contact with Sandvik and will continue to communicate regarding our concerns but from what we can gather the seal and greasing system is a design flaw and inquiring if anyone has experienced similar issues? I can share pictures, drawings and additional information if requested, attempting to keep the summary as short as possible.

Thank you

Chris